The Art and Science of Tinted Lenses

Tinted lenses can offer more than just aesthetic, they can also provide functional benefits such as enhanced contrast, improved visual comfort, and glare reduction. From fashion-forward gradients to deep and therapeutic solid colors, lens tinting is both an art and a science. However, creating a consistent and accurate tint, regardless of your skill or elite-level processing, can be surprisingly complex — especially when matching a sample or previous lens. More complex still is managing the expectations of the patient. Let’s take a deeper look into the tinting process and discover why even the most experienced laboratories sometimes produce tints that vary slightly from expectations.

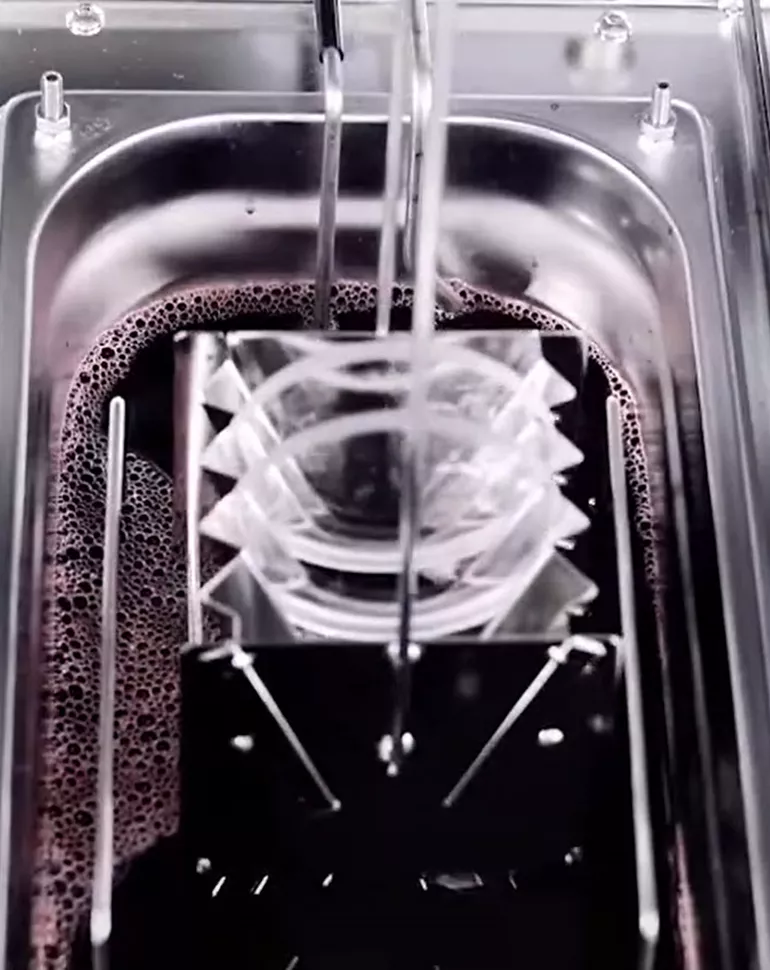

The Tinting Process

Almost all lens tinting is done on plastic lenses, the most common types are CR-39 and polycarbonate, using heat-based dye baths. The lenses are submerged in tanks filled with a mixture of water and specially formulated dyes, typically heated between 180°F to 205°F (82°C to 96°C). The heated bath opens the surface pores of the lens and allows the dye to penetrate. The duration of time in the dye bath and the temperature of the solution are critical, as both variables directly affect the color and how dark the final tint appears.

For polycarbonate lenses, which are less porous than CR-39, a scratch-resistant hard coat is required, and that hard coat also needs to be tintable. Because of these factors it is very common for a lab to use a semi-surfaced lens blank instead of a finished lens blank when tinting polycarbonate lenses. In addition, not all coatings accept dye equally, which is another factor in variability when tinting lenses.

After tinting, the lens is rinsed and sometimes cooled to lock in the color. Because tinting is a surface-level process, it can fade over time due to UV exposure or repeated cleaning. This is why older, gray sunglass lenses may appear to have a purple hue, which is one of the reasons it is difficult to match old lenses.

Tint Density and Color Theory

Tint density refers to how dark a tint appears and is often expressed as a percentage. A 20% gray lens lets in 80% of light, while an 85% gray lens allows only 15% light transmission. The density of the lens can be adjusted by altering the immersion time, dye concentration, and bath temperature. All of these variables can be used to manage tint density, though they are not the same for each material. For example, polycarbonate lenses will require more time to reach the same density as a CR-39 lens. And due to the non-porousness of polycarbonate, it may never reach the same level of tint density as CR-39.

Transmission percentages can also be referred to by a numerical category, seen below.

| Category | Light Transmission | Description |

Usage |

| Category 0 | 80 – 100% | Very light tint / Clear | Indoor use, fashion |

| Category 1 | 43 – 80% | Light tint | Overcast days, fashion |

| Category 2 | 18-43% | Medium tint | Mixed sunlight |

| Category 3 | 8 – 18% | Dark tint | Bright sunny days, driving |

| Category 4 | 3-8% | Extremely dark tint | Extreme sun, not suitable for driving |

More than 90% of sunglass tints are gray or brown, however, occasionally lenses are tinted to another color like blue or yellow. When adjusting the tint color, labs follow basic principles of color theory. Just like mixing paint, lens tints are affected by additive combinations. Neutral gray can turn greenish if too much yellow is added. Brown lenses dipped in blue will result in a muted or slate gray. Blue over yellow may produce a murky green. Understanding how each color works with or against each other helps tint technicians predict the visual outcome of layered dyes. Layered colors are yet another variable when it comes to matching tints.

Because dyes are transparent, the final appearance is also influenced by lighting conditions and the patient’s own perception. What looks like a warm brown under incandescent light might look more like cool gray in daylight. The warmth or coolness of the lighting will have a significant impact on the visual perception of the tint color.

Why Matching Tints is So Difficult

One of the most challenging requests in lens tinting is to match an existing sample, especially if the sample lens has faded over time, came from a different lab, or was produced on different base material, like a stock sunglass frame.

The four most common challenges to managing tint expectations:

- Base lens material: Even clear lenses have slight color tones, some may be slightly yellow, blue, or green. This will affect the final color result once dyed.

- Lens coatings: The hard coat used on polycarbonate or high-index lenses may tint differently from that on CR-39. Some coatings resist dye absorption, requiring longer tint times or special pre-treatment.

- Tint bath variation: The tint bath can vary by ratio of tint dye and water. Even when using the same brand and formula, a new batch of dye might result in subtle shifts in hue.

- Human perception: Perhaps most surprisingly, patients often perceive color differently based on memory, lighting, and context. A 75% gray lens may look darker or lighter from one day to the next, depending on surroundings and mood.

Setting Expectations

Despite the challenges, most labs produce beautifully tinted lenses that meet most patient needs. But when a patient asks for an exact match, especially to an old, faded lens, it’s important for eye care professionals to educate and set expectations:

- Slight variations are normal and often unnoticeable in day-to-day wear.

- Lighting dramatically affects perceived color.

- Changes in material, thickness, frame, treatments, and many other variables will affect the tint color.

- Even with precise tinting methods, small variations in tint appearance can occur due to differences in lens materials, coatings, or dye absorption rates.

Clear communication is essential when helping patients understand the nuances of lens tinting. While every effort is made to meet the requested specifications, it’s helpful to explain that tint outcomes can be influenced by multiple factors outside of the lab’s direct control. Encouraging patients to view tinted lenses under natural daylight and judge them on how their vision looks out of them, instead of aesthetically indoors, can also help set realistic expectations for how the tint will appear in everyday use.

By understanding all the variables discussed, together we can help manage expectations between labs, ECPs, and patients to ensure the best possible outcome for tinted lenses.

Your HOYA laboratory customer service team is happy to help you provide the best possible outcomes for your patients.